Motor Controller Verification Project

For this project, we had to perform four tests on a motor controller board. The purpose was to teach us how to use various equipment, such as the function generator (GBF), oscilloscope, stabilized power supply, among others. Finally, this SAE's goal was to compare the compliance of the manufacturer's motor board with the data provided in the manufacturer's documentation and the information provided in the project brief.

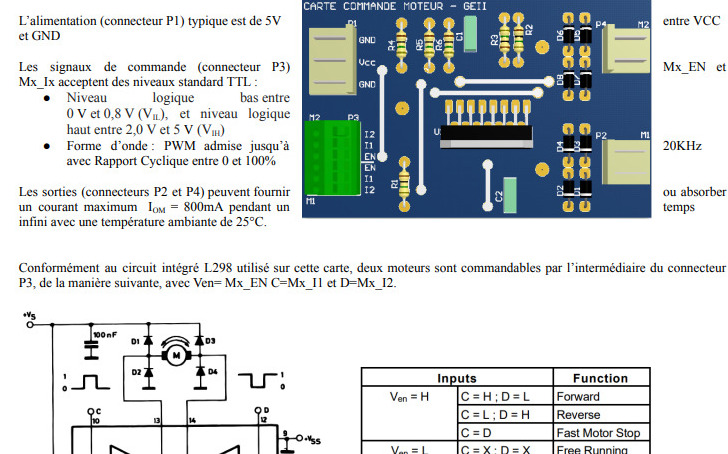

Here are the project brief and datasheet

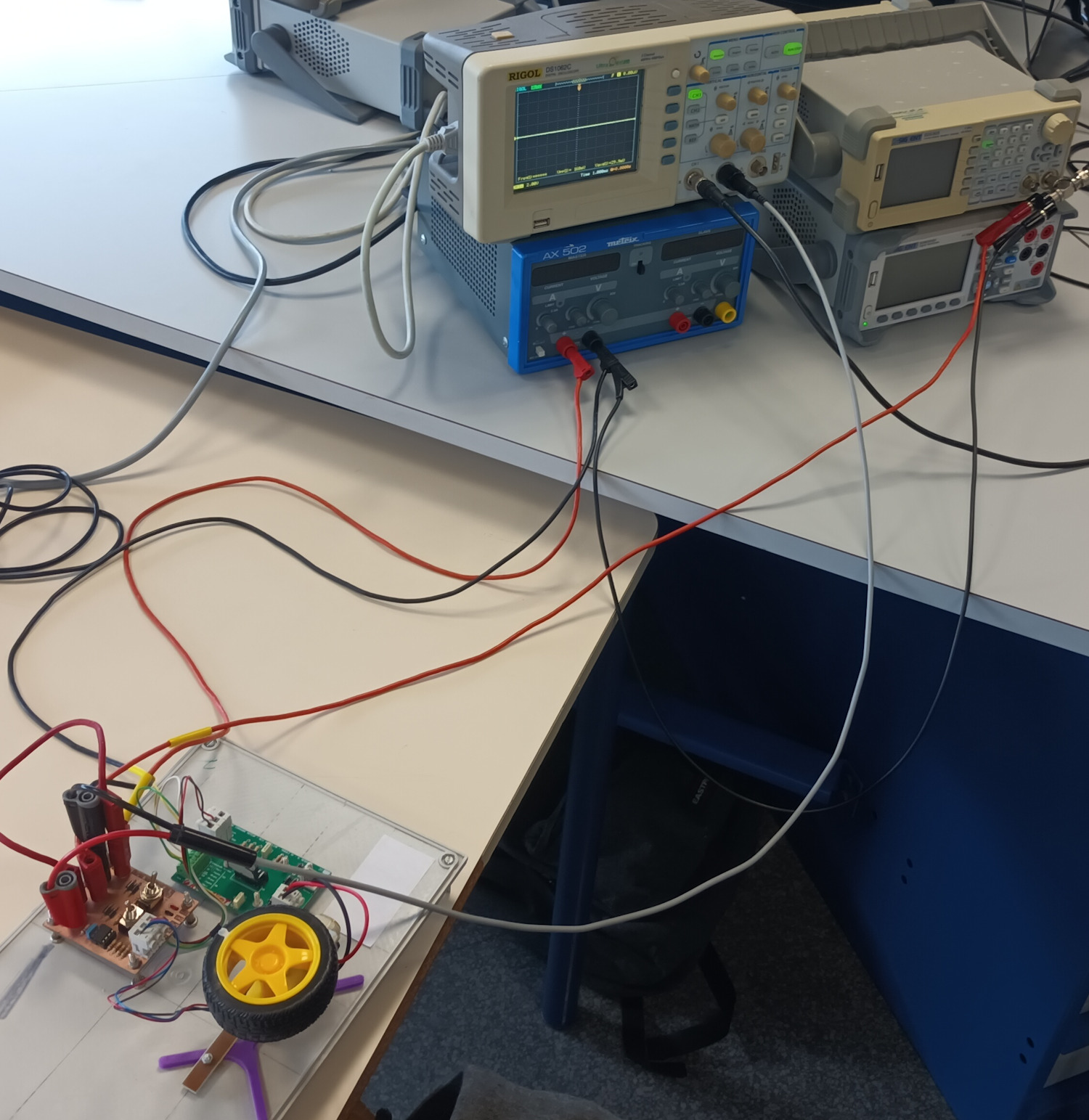

Adjust the devices and make the connections.

This step involved adjusting and connecting the devices to prepare them for testing. This ensures reliability and accuracy of the results and avoids problems.

Trace

Self-assessment

Adjusting the devices properly wasn't an issue for me.

Test 1 & 4: Board compliance verification.

The board compliance verification ensures that the interface validates the truth table for rotation direction control, speed control by PWM signal, speed signal measurement, and tests one channel of the motor board to verify the motor status.

Resources Used

Documentation: Project brief

Test 2: Saturation and consumption value verification.

This test verifies the saturation and consumption values of the motor by measuring no-load and full PWM duty-cycle consumption and verifying they don't exceed typical values. It also checks the motor's input voltage under the same conditions to confirm typical saturation voltages.

Resources Used

Documentation: Project brief

Pedagogical: Another student

Test 3: Switching times verification.

This test aims to validate the typical rise time, fall time, and delays of the various switches.

Resources Used

Documentation: Project brief

Pedagogical: Energy course

Conclusion

This project taught me how to use the devices available at the IUT and develop the competence to verify through various tests, as well as maintain by designing the motor board's testing protocols.